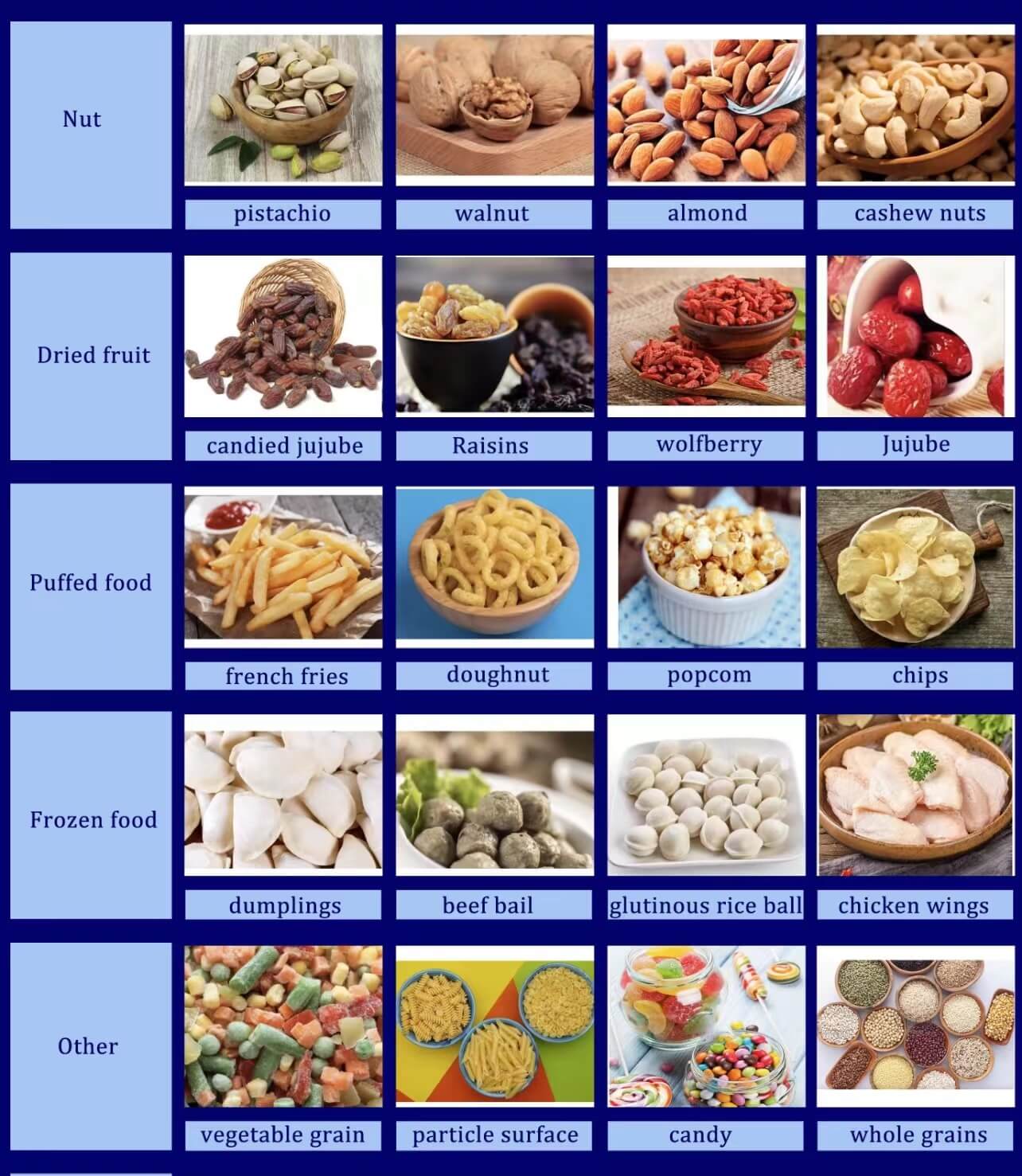

Snack Packing Machine

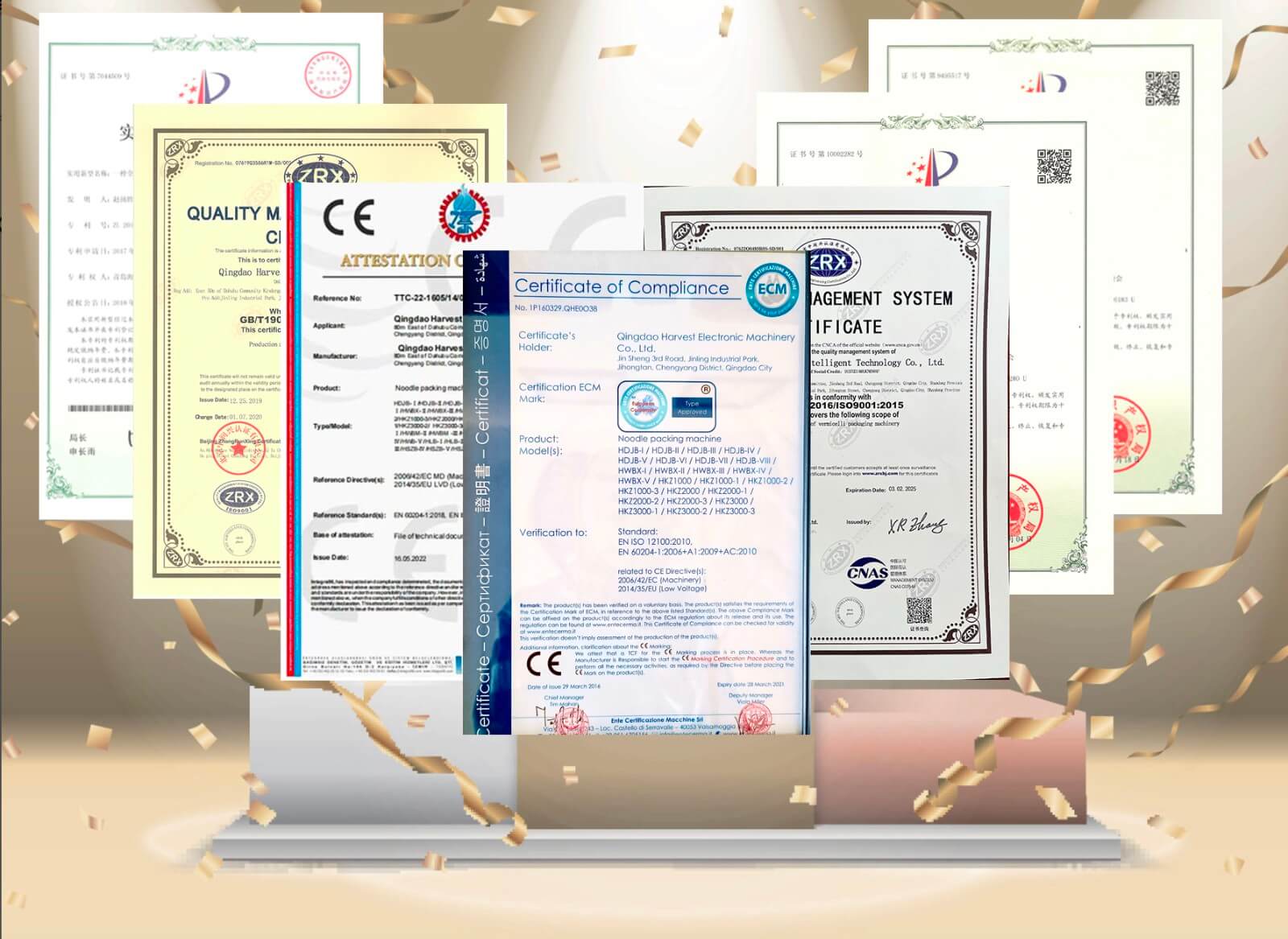

Hfirst Snack Packing Machine has 20 years of research and development and manufacturing experience in China. Applicable to bulk strip-shaped materials such as: dry food, Frozen food,snack,nuts, chips, automatic weighing and packaging. Fully automatic and high-precision weighing and high-speed packaging, controlled by a highly intelligent system, with strong stability and stainless steel material meeting food grade standards. The 8000 square meter production and manufacturing workshop has a R&D technical team of over 20 people and over 100 employees. Our packaging machine have CE and ISO9001 certifications, over 30 national technology patents, and have led the development of Chinese national technical standards for noodle packaging.Products are sold to countries such as the United States, North America, South America, Africa, and Europe.

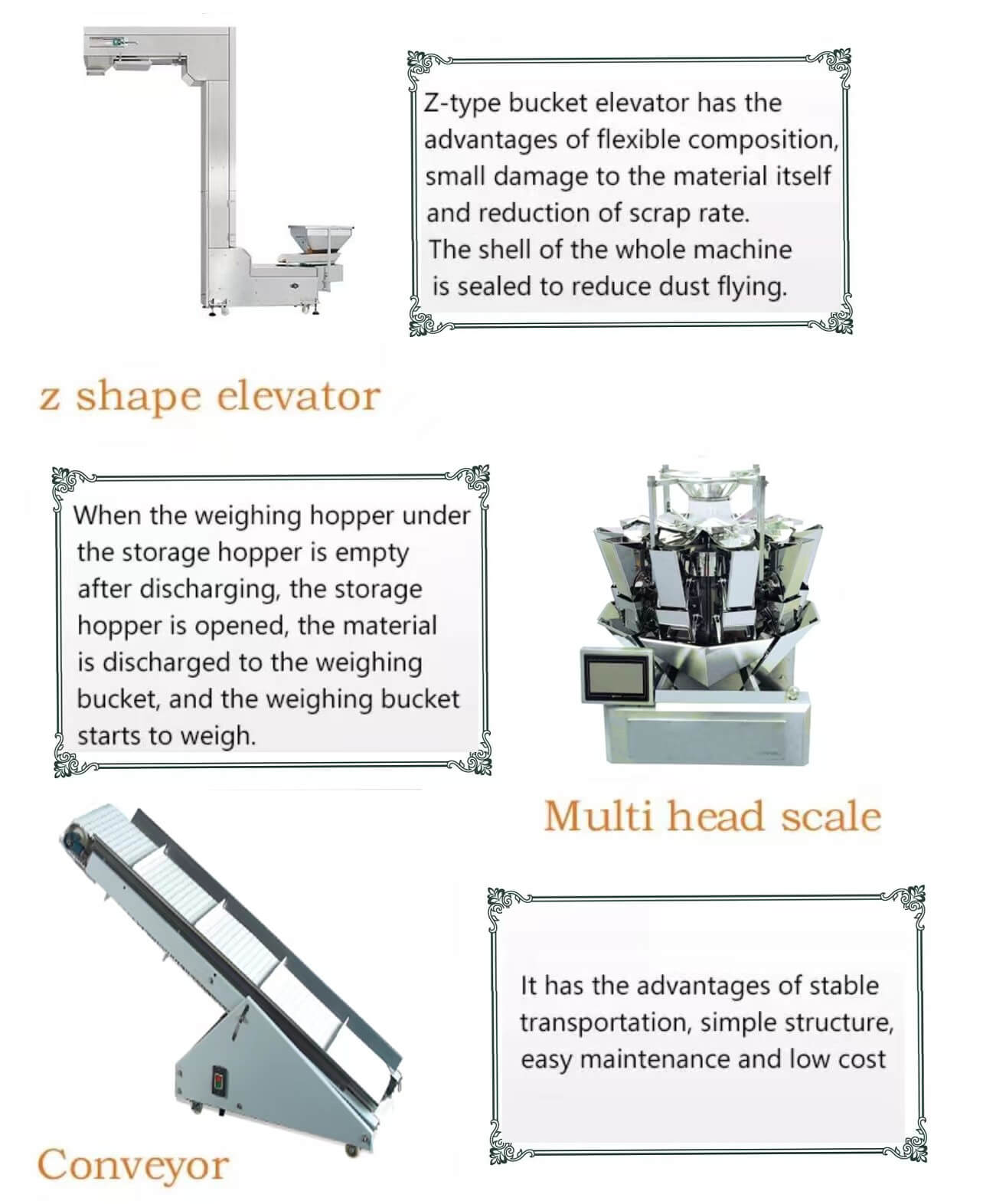

Details

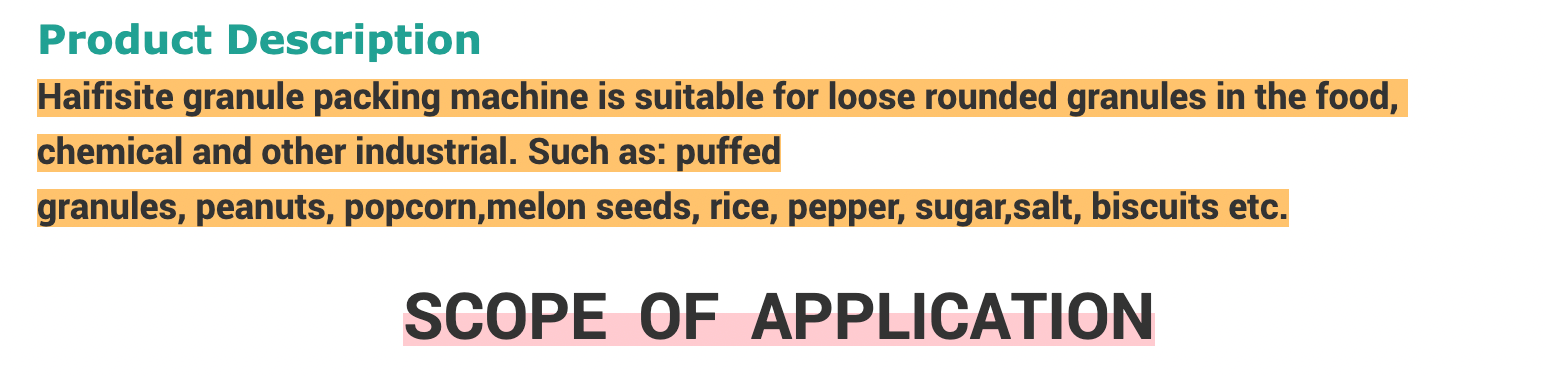

Snack Packing Machine

It is suitable for weighing and packing grain, stick, slice, globose, irregular shape products such as puffy food, snacks,candy,jelly,seeds,almonds, chocolate, nuts, pistachio, pasta, coffee bean, sugar, chips, cereals, pet food, fruits, roasted seeds,frozen food,vegetable,fruits, small hardware..

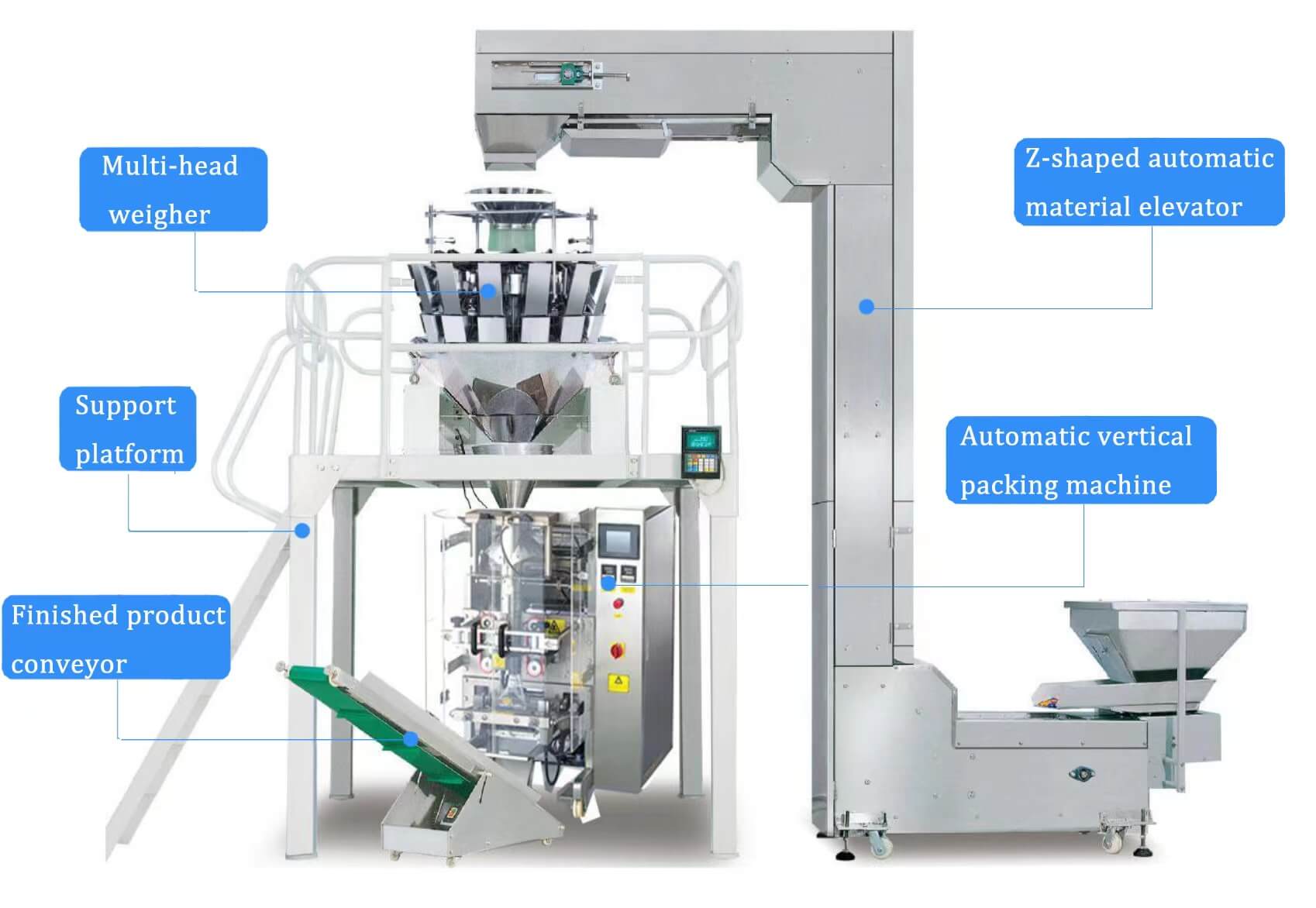

1. Adopting PLC from Japan or Germany to make machine run stable. Touch screen from Tai Wan to make operation easy.

2. Sophisticated design on electronic and pneumatic control system makes the machine with high level of precision, reliability and stability.

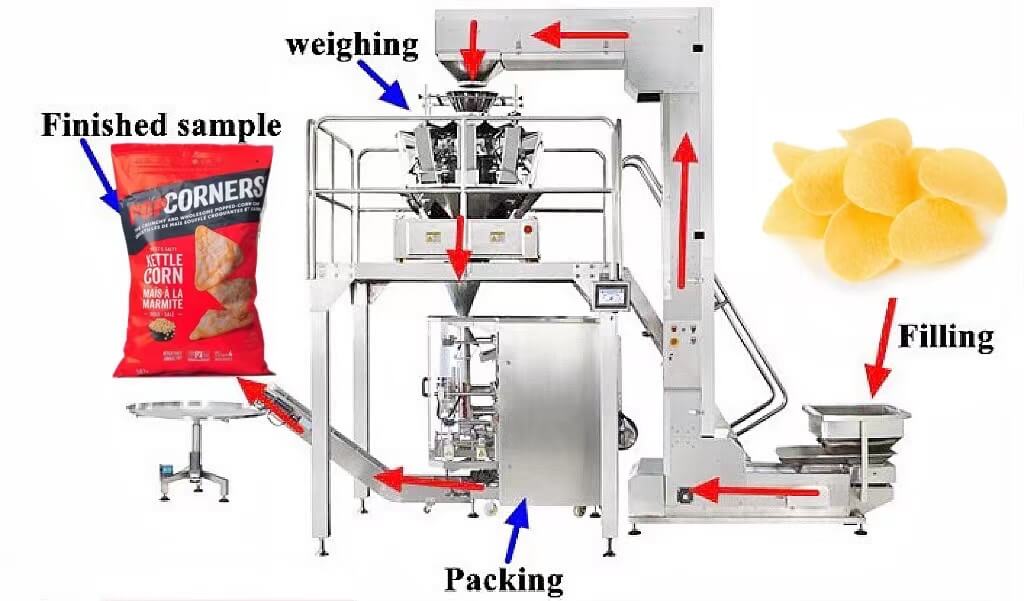

3. Single-belt pulling with servo of high precise positioning makes film transporting system stable, servo motor from Siemens or Panasonic.

4. Perfect alarm system to make problem solved quickly.

5. Adopting intellectual temperature controller,the temperature is controlled to ensure neat sealing.

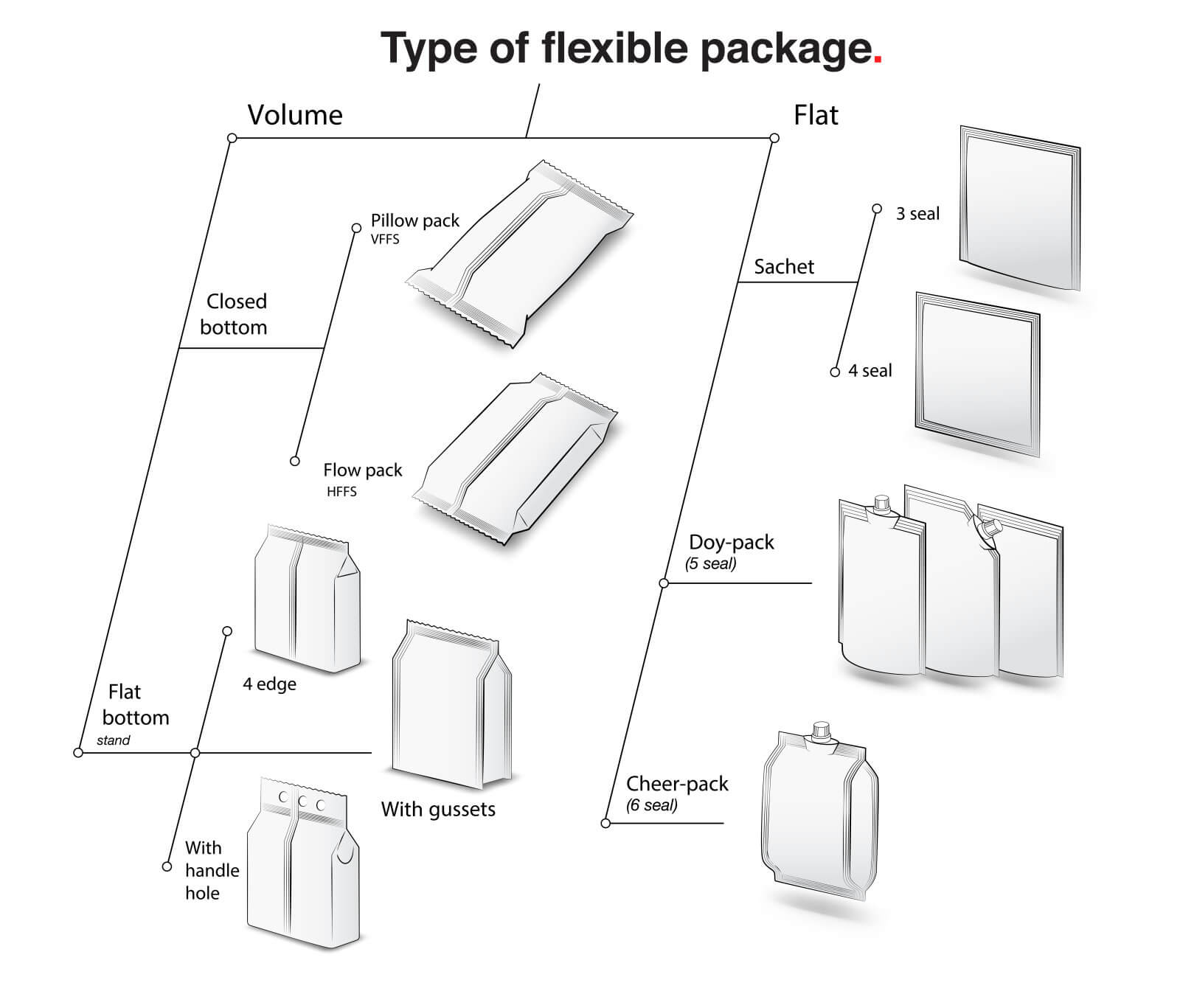

6. Machine can make pillow bag and standing bag (gusseted bag) according to customer's requirements. Machine also can make bag with punching hole & linked bag from 5-12 bags and so on.

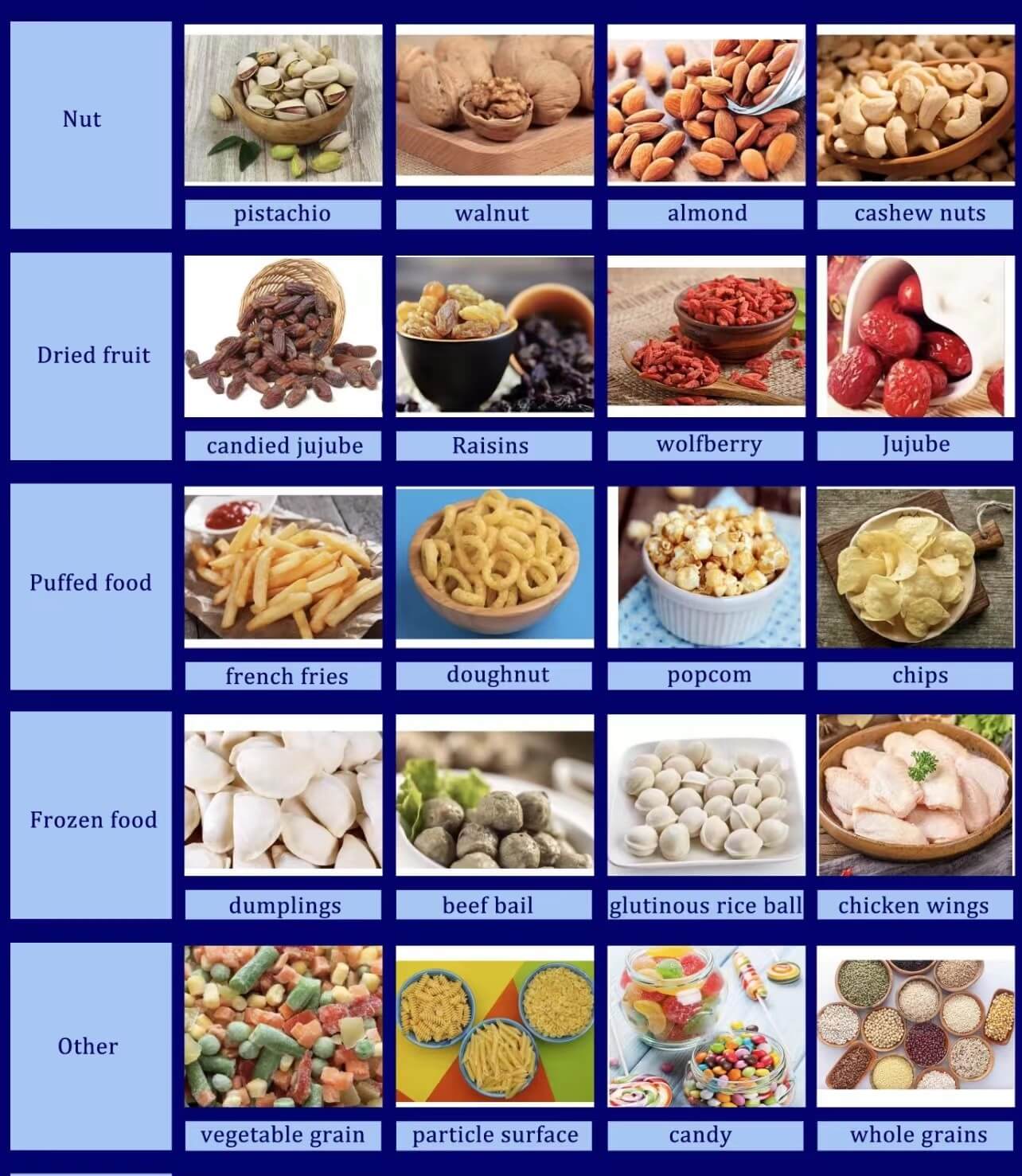

7. Working with weighing or filling machines such as multihead weigher, volumetric cup filler, auger filler or feeding conveyor, process of weighing, bag making, filling, date printing, charging (exhausting), sealing, counting and delivering finished product can be completed automatically.

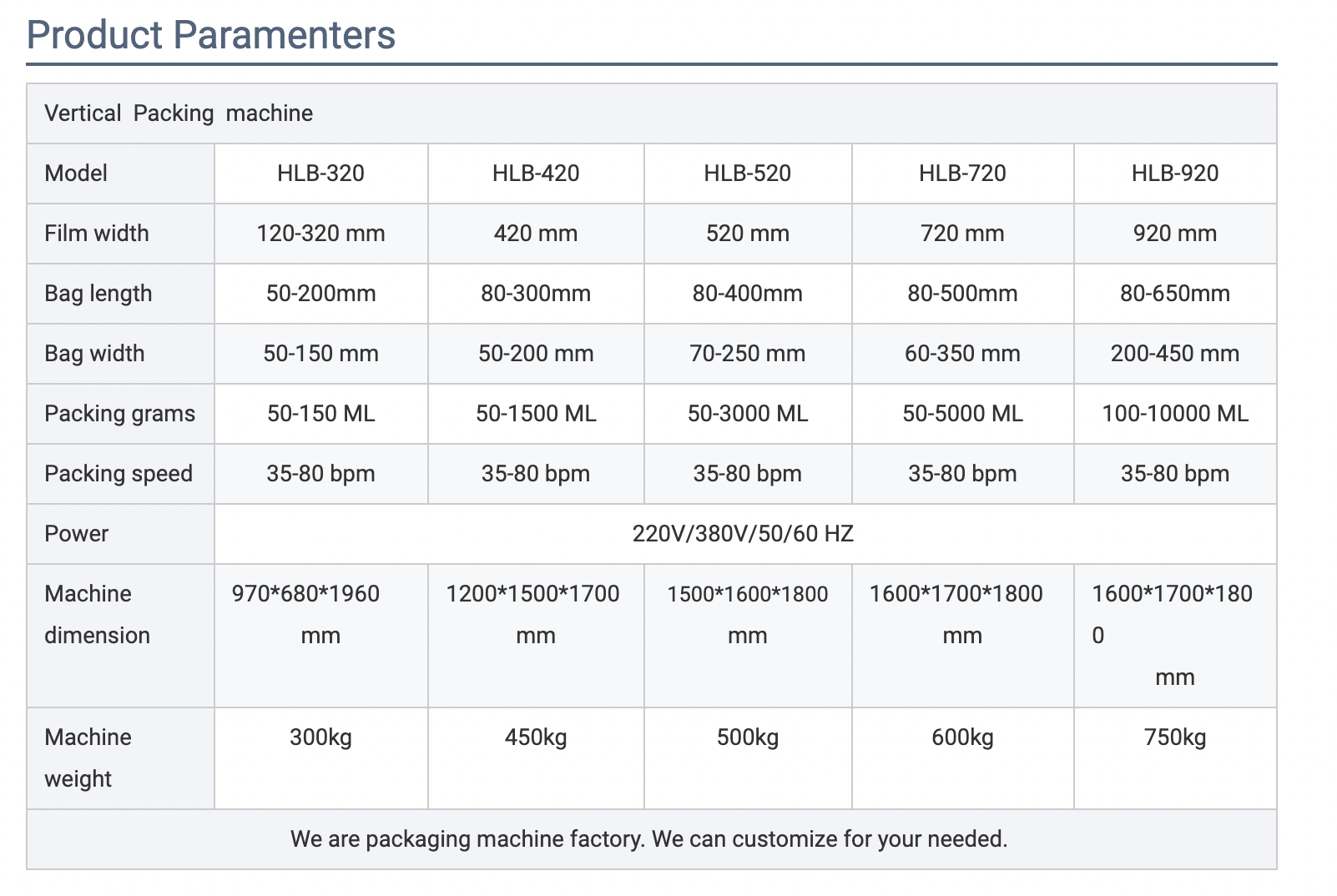

Vertical Packing Machine

Optional Device

1. Printer(ink jet, Thermal transfer, color ribbon date printer)

2. Nitrogen device

3. Labeling device