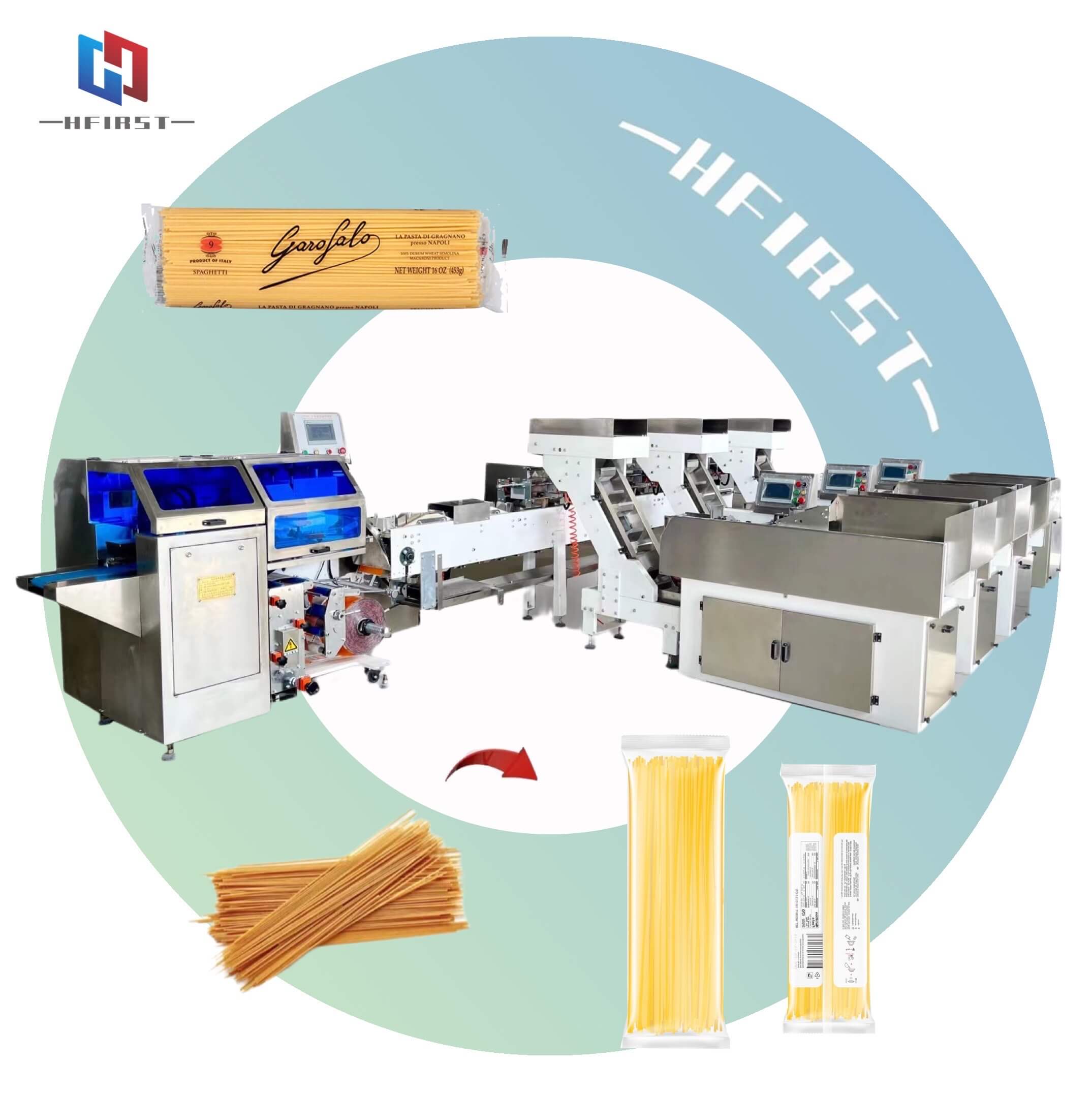

Spaghetti Packaging Machine

Embrace the innovation customization and flexibility. No lower price but always worth its value. Provide the perfect packing solution based on the customers' detailed requirements. Extremely high quality of machine and professional technical after-sales service. Hfirst Spaghetti packaging machine has 20 years of research and development and manufacturing experience in China. Applicable to bulk strip-shaped materials such as: noodle, Spaghetti automatic weighing and packaging. Fully automatic and high-precision weighing and high-speed packaging, controlled by a highly intelligent system, with strong stability and stainless steel material meeting food grade standards. We have CE and ISO9001 certifications, over 30 national technology patents, and have led the development of Chinese national technical standards for noodle packaging. With more than twenty years expertise and technical experience, do better in this flow packing filed and get our customers' great satisfaction.

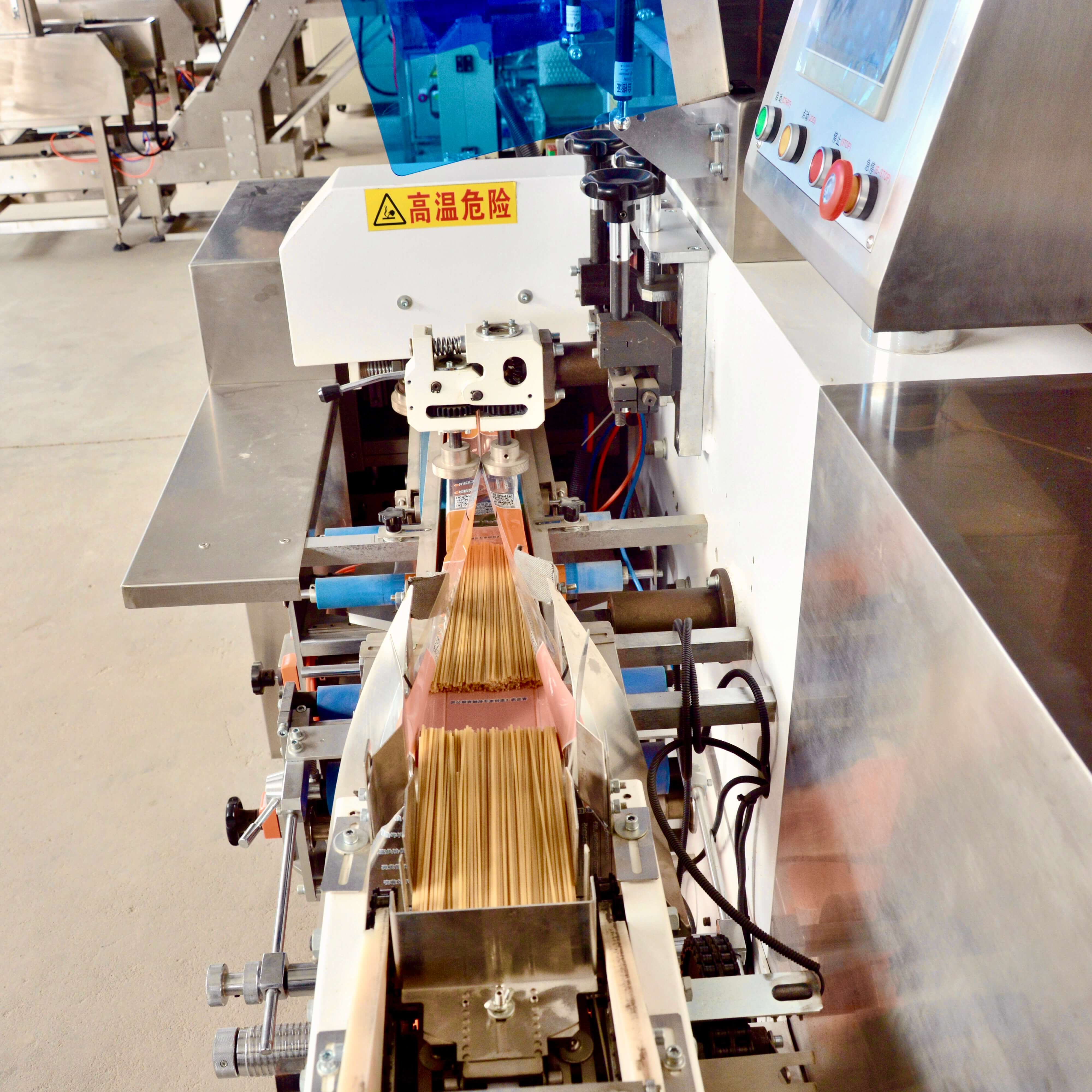

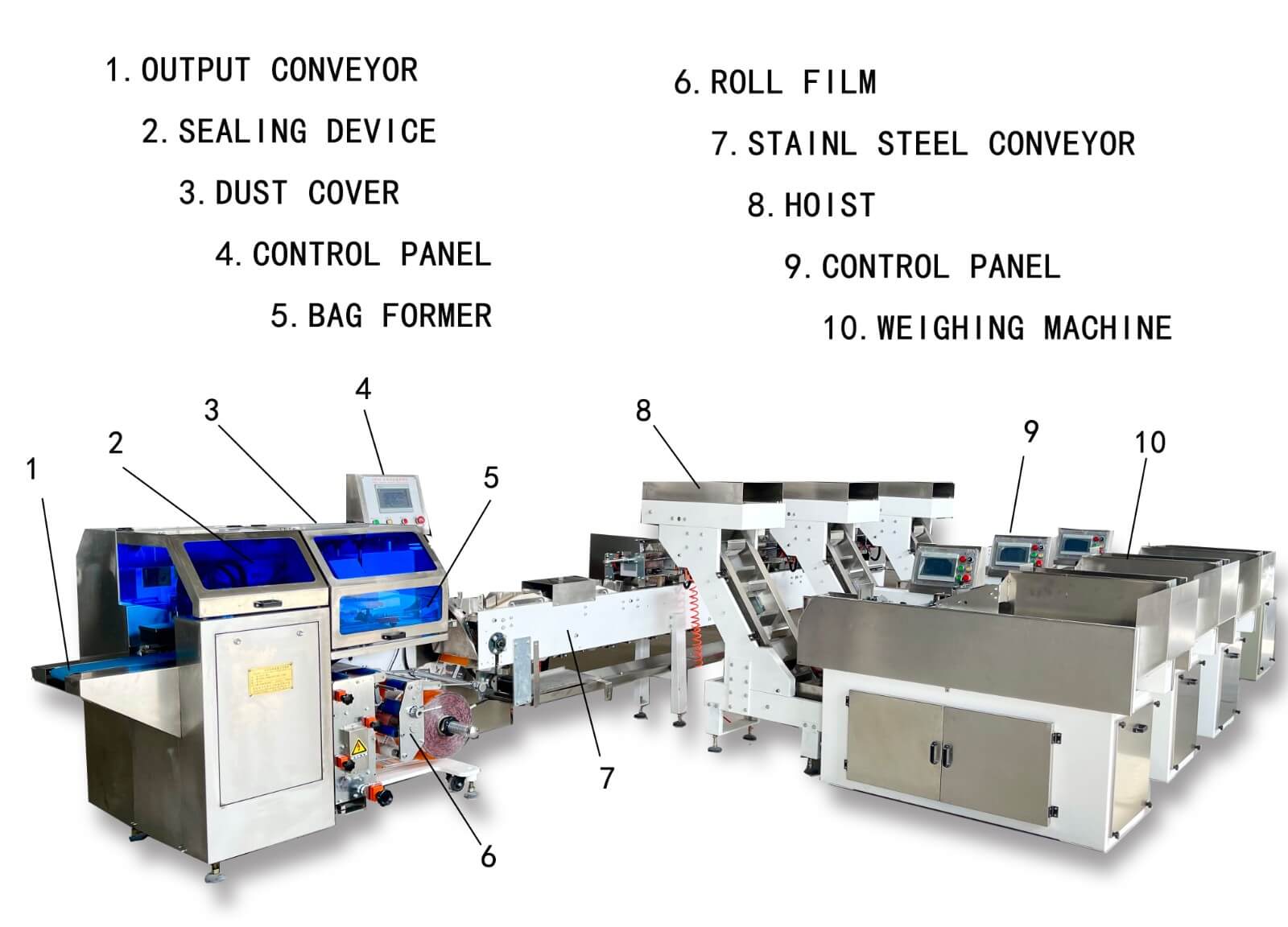

Details

Spaghetti Packaging Machine

Use Environment Requirements of spaghetti Packing Machine:

Site requirements: Indoor use, the ground is flat, no vibration and bumps.

Ground requirements: For hard non-conductive floors (such as concrete, floor tiles, etc.)

Ambient temperature: -5~40℃

Relative humidity: <75%RH.

Dust: No conductive dust.

Gas: No flammable and explosive objects and gases, no corrosive gases that seriously damage metals.

Altitude: ≤1000m

Grounding Requirements: Independent, safe and reliable grounding environment.

Grid requirements: There is a stable power grid, and the fluctuation range of the power grid does not exceed ±10%.

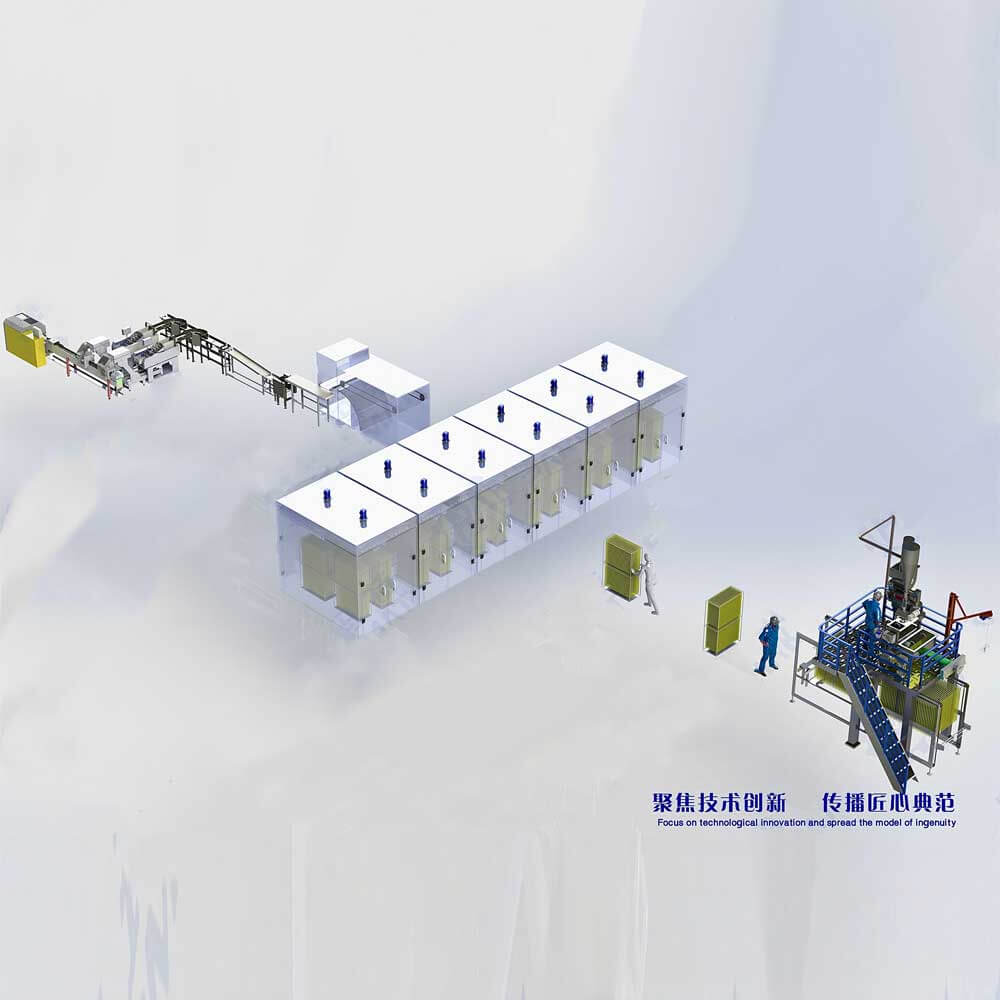

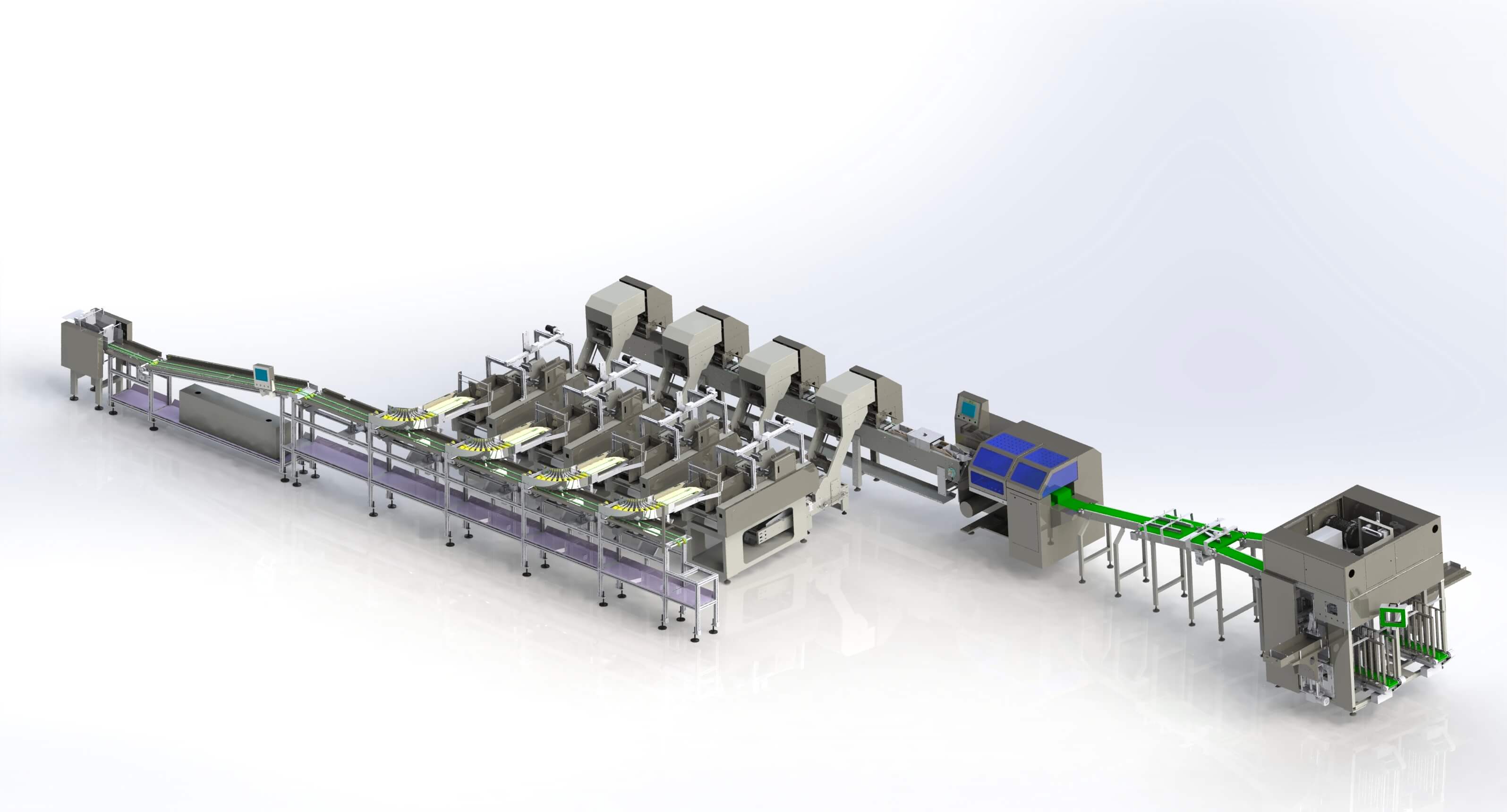

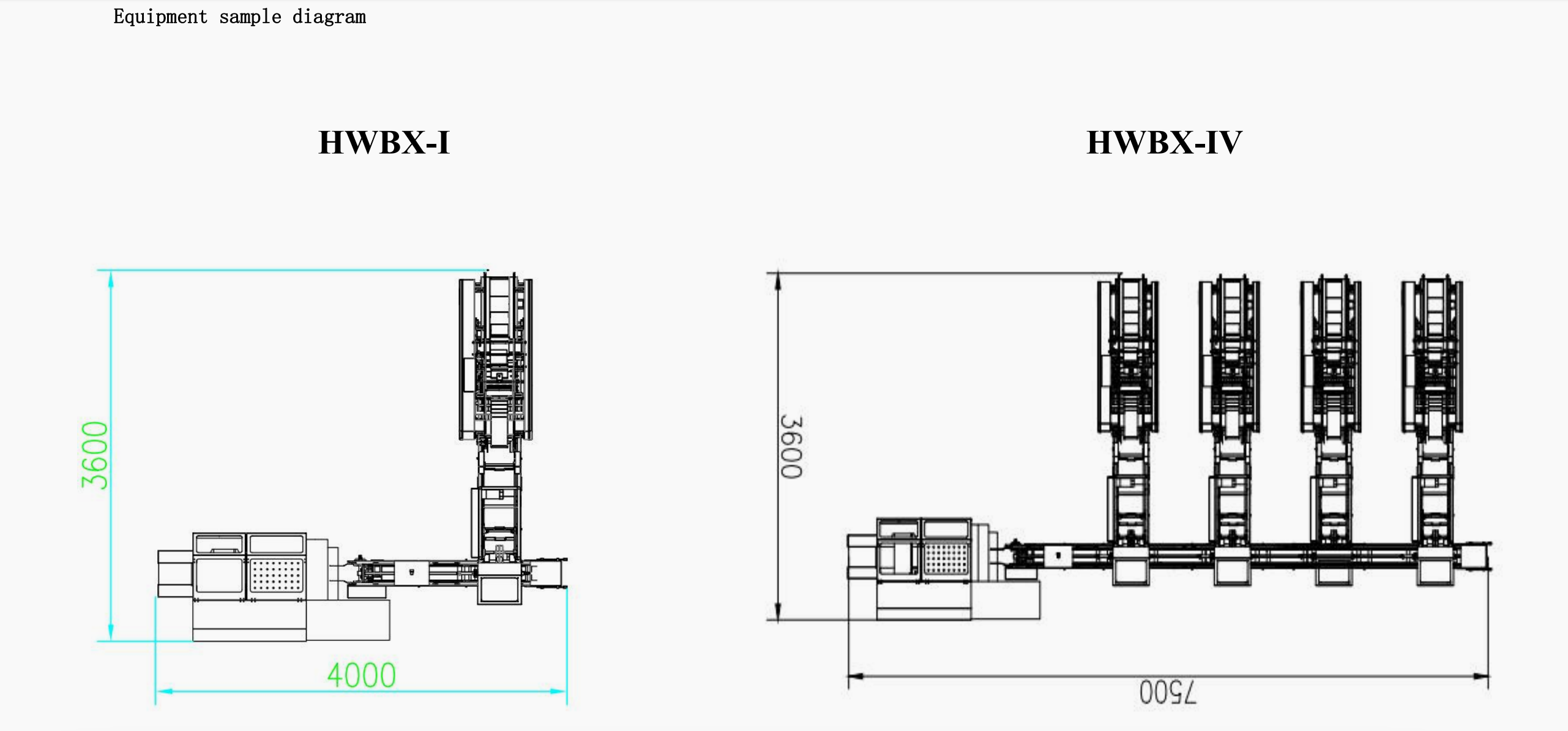

According to your needs, we will provide you with fully automatic intelligent packaging production line solution.

Fully automatic spaghetti packaging machine

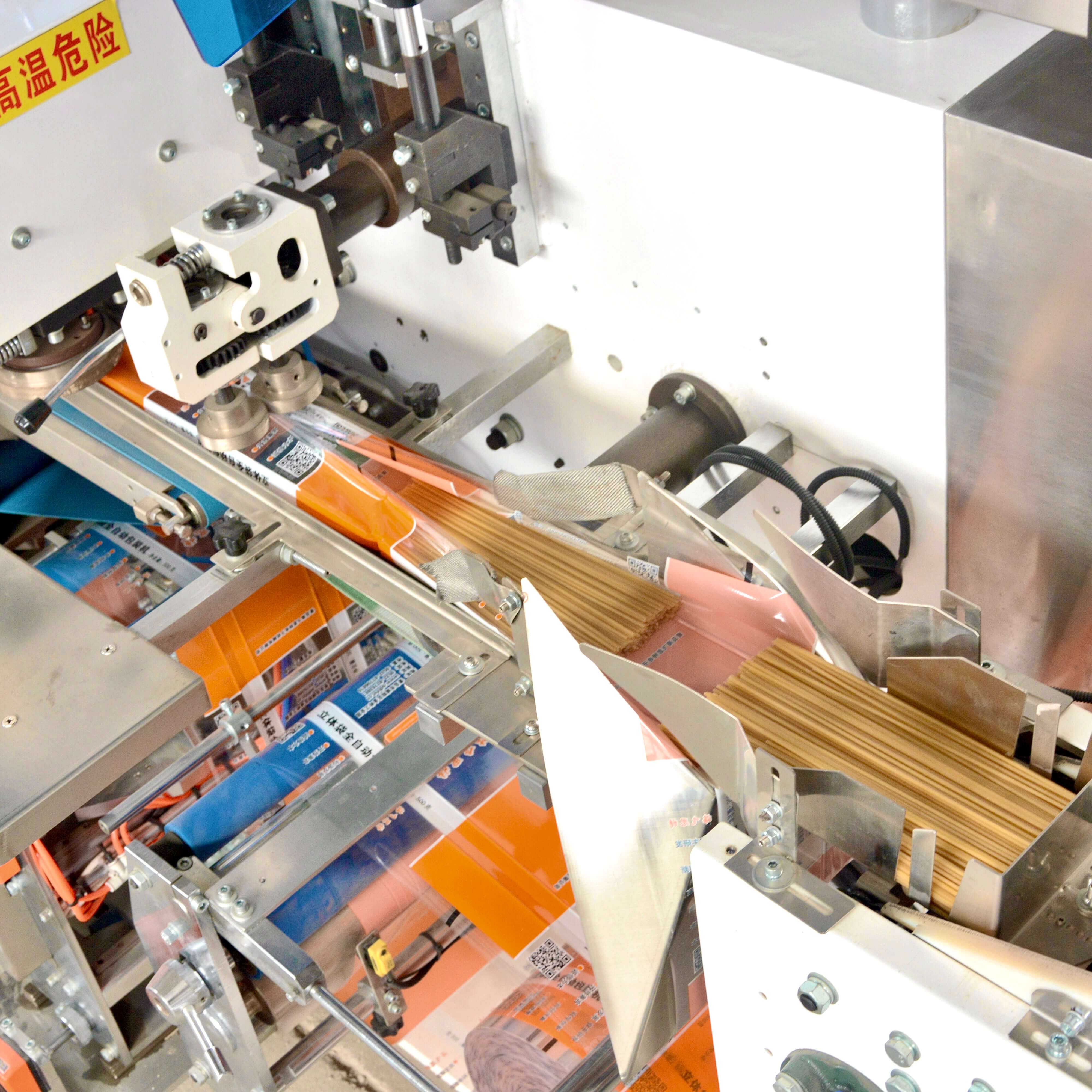

1. Intelligent, digital servo motor control system for spaghetti packaging machine.

2. Double driving vertical sealing, automatic opening and closing structure.

3. Tansverse sealing and cutting center can with packing height adjustment.

4. The feeding position in operation can be adjusted at any time.

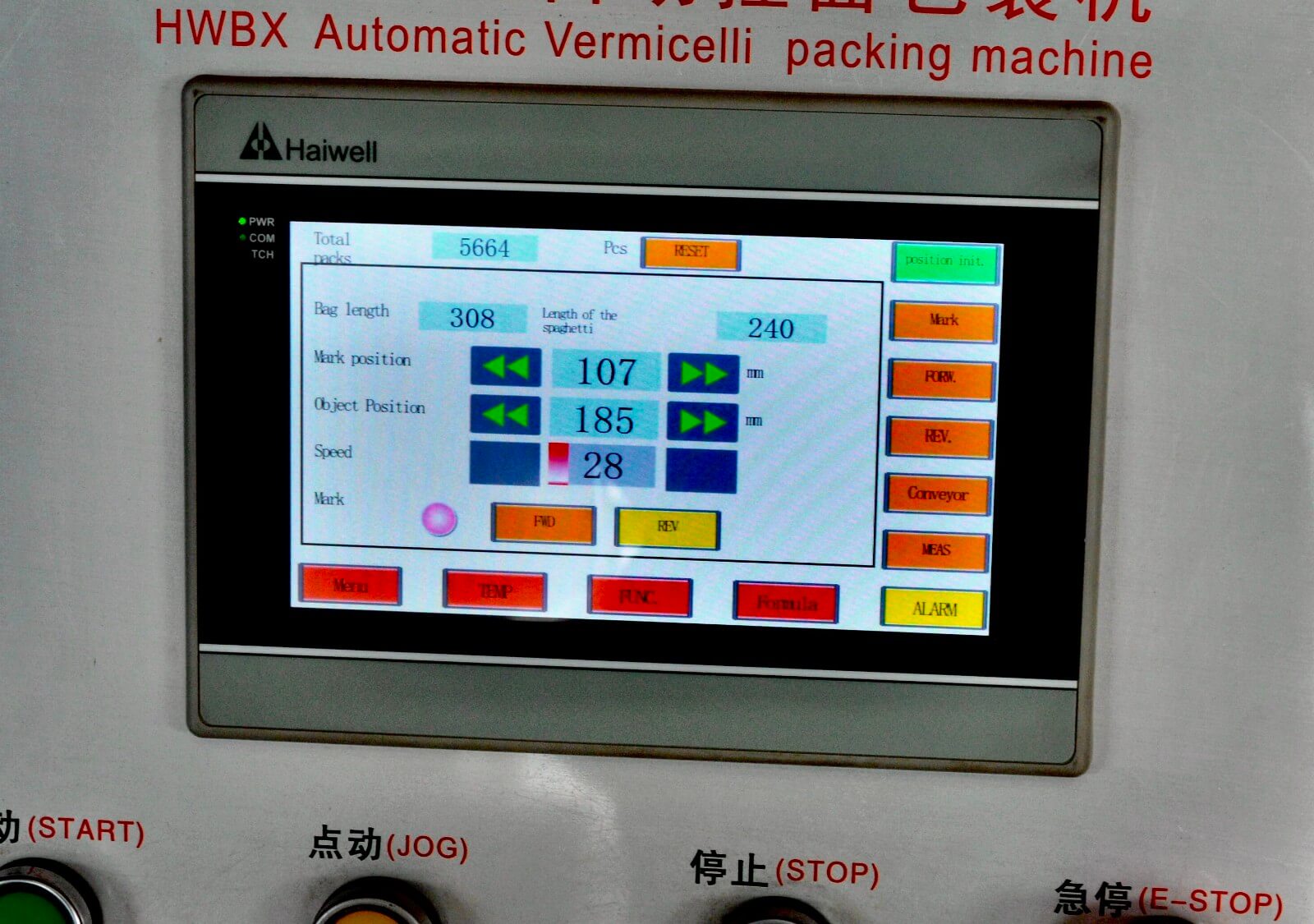

5. LCD display, can be set, display operating status, parameters and fault.

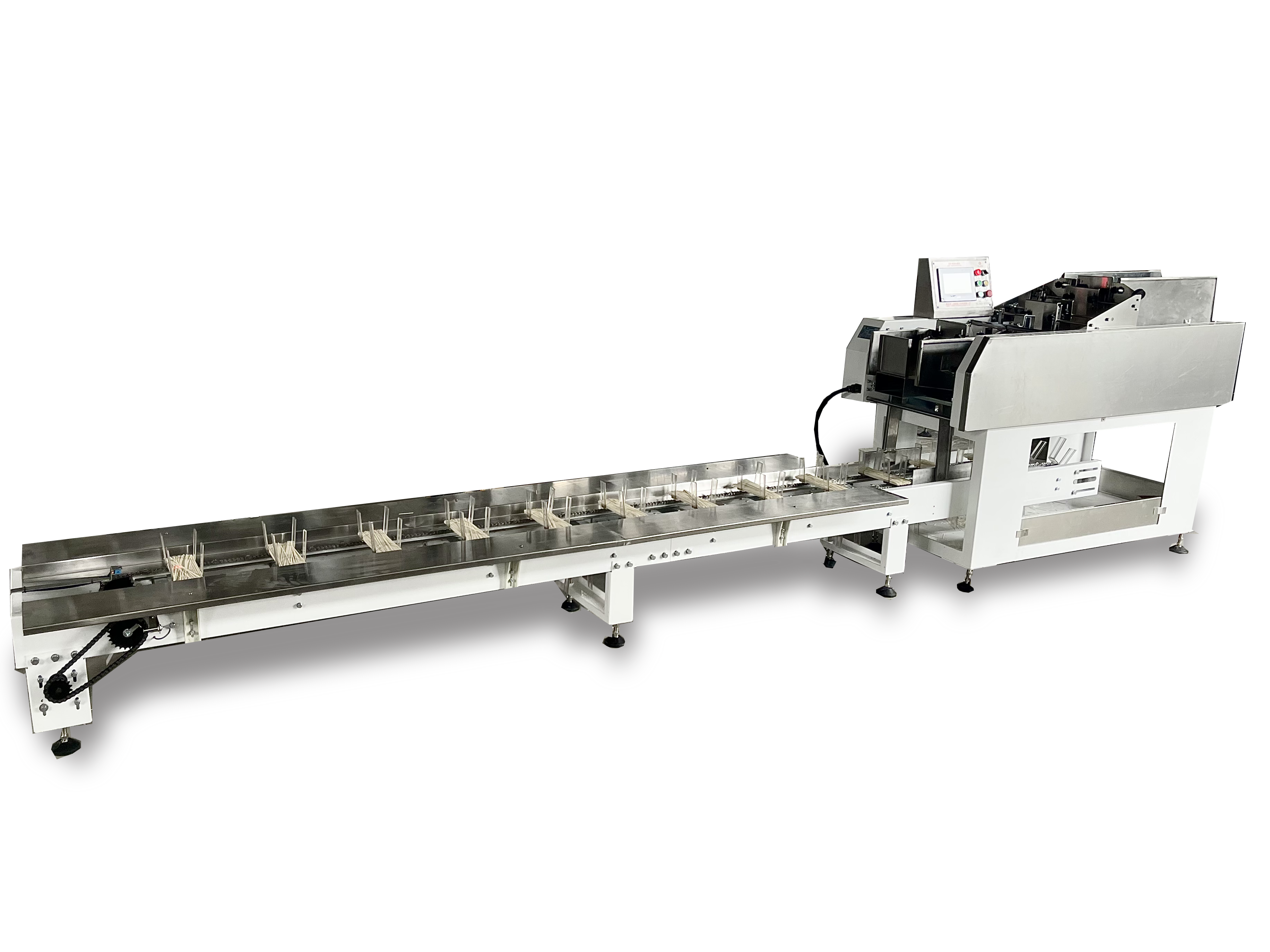

6. Part of the conveyor has the advantages of compact structure , adopts the material box structure , solves, the conventional scraper structure need t be replaced frequently and appearance defects.

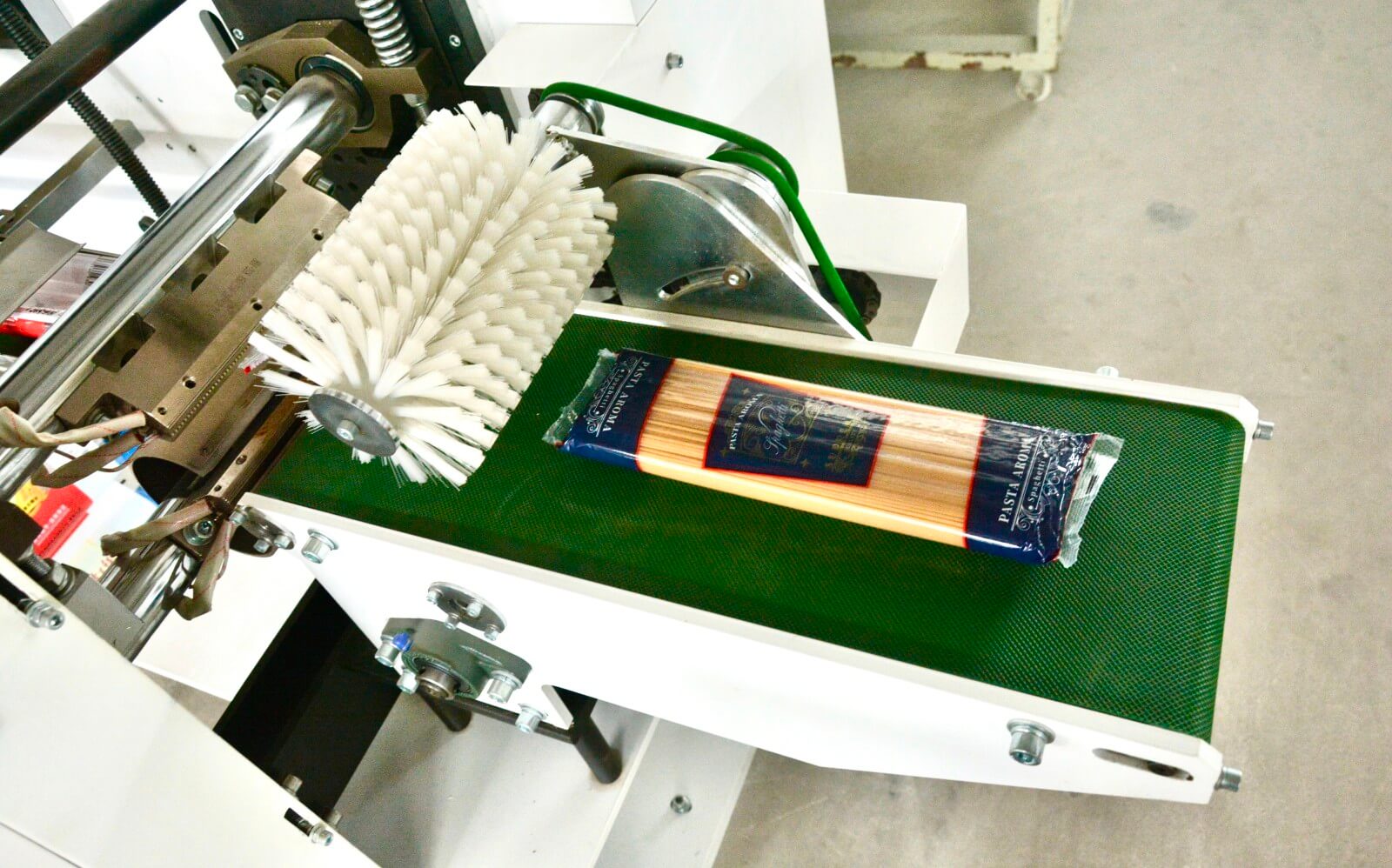

7. Our Spaghetti packing machine has a unique automatic flush device, ensure that the qualified rate of the finished packaging vermicelli.

8. Color code tracking point automatic positioning, automatic with the standard; packaging bags, automatic measurement of memory.

9. With air defense, anti cutting function, saves the packaging cost.

10. Automatic weighing machine, host core system and stainless steel conveying line are exclusive patents.

11. Our Spaghetti packaging machines are exported to the United States, Italy, Africa and other countries and are well received. It is a multi-year spaghetti packaging machine supplier for China's well-known enterprise COFCO group, the listed company Chen Keming Food Co., Ltd., the well-known brand golden dragon fish and the white elephant group.

Main technical parameters

1. | Measurement range | 100-500g / 300-1000g |

2. |

Packing speed Single set | HWBX-I:15-20 bags/min |

HWBX-IV:65-70 bags/min | ||

3. | Power supply | AC 220V 50HZ |

4. | Total gas consumption of the equipment | 0.05m³/min/cover |

5. |

Power: | HWBX-I:5kw |

HWBX-IV:7kw |

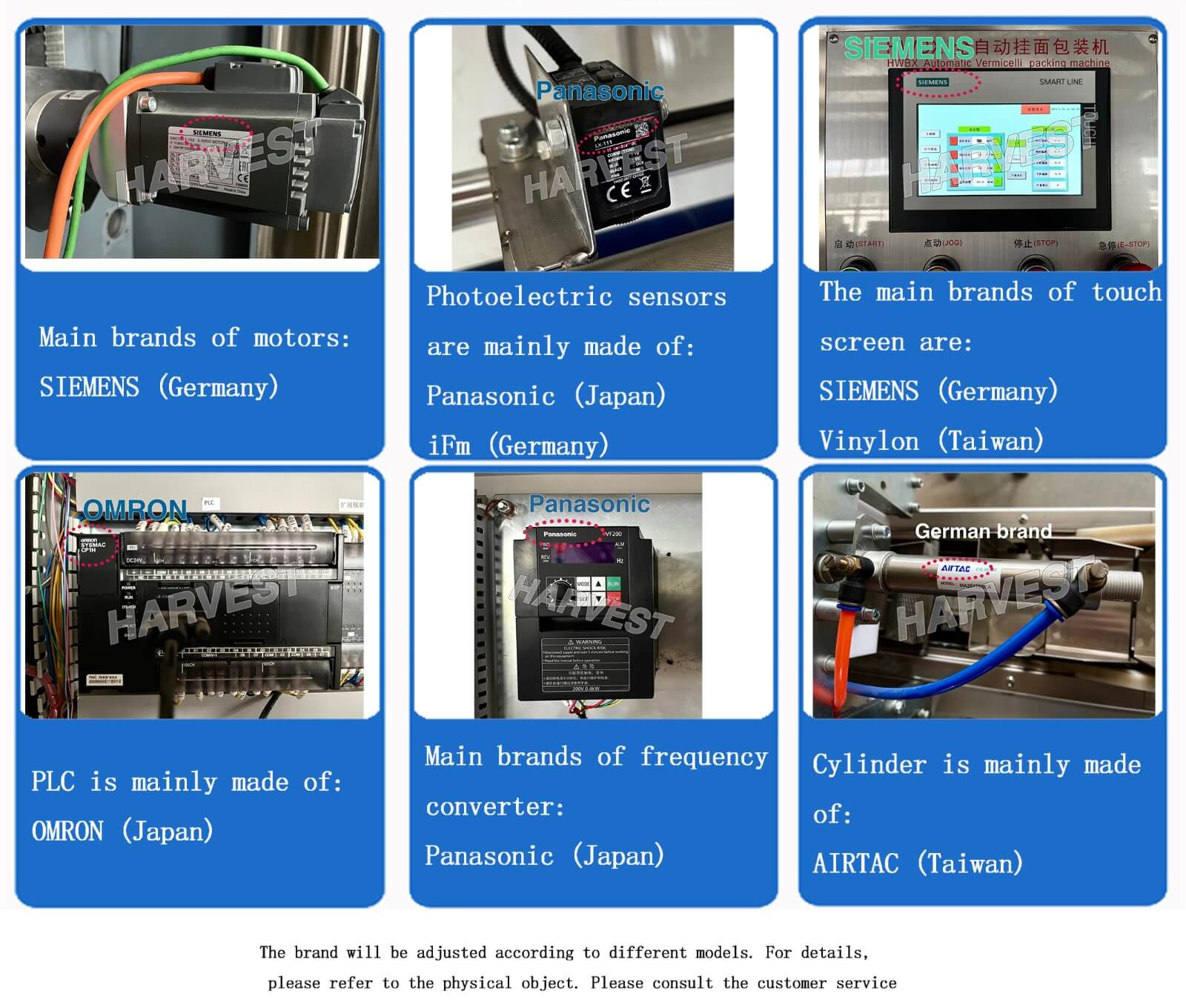

Electrical configuration of main equipment

Main electrical configuration | ||||

NO. | name | model | brand |

|

1. | PLC system | X40DT-D | Omron (Japan) |

Packaging Machine |

2. | Touch-screen | TK6070IP | Weilun (Taiwan) | |

3. | Photoelectric sensor | PH-Q23-A1-020 | Kerui | |

4. | Proximity switch | M1204N-03U2 | Bideke | |

5. | Solid-state relay | DD4825/DA4840 | Meel (Shanghai) | |

6. | Switch on the power supply | NES-50-24V | Ming Wei (Taiwan) | |

7. | Servo system | EMJ –08/PROWET-E-08A | Eston | |

8. | Color code photoelectricity | QS18VN6CV15/LX- 111 | Bonner(USA)/ Panasonic (Japan) | |

9. | Photoelectric sensor | PM-K45 | Panasonic (Japan) | |

1. | PLC system | XC3-24T-E | Xinjie |

Weighing Machine |

2. | Touch-screen | TG-765-MT | Xinjie | |

3. | Weighing Module | TR700-FT | Zhuhai Changlu | |

4. | Switch on the power supply |

100/ 150-24V |

Ming Wei (Taiwan) | |

5. | Rotary Solenoids | MX 7235MQ30 | Qingdao Seahawk | |

6. | weight sensor | L6N-C3 | AVIC Survey | |

7. | Main electric motor |

| ZD or Miley | |

8. | SS-22 | ZD | ||

9. | Solid-state relay | DA4825/DD2225 | Meel (Shanghai) | |

10. | Intermediate relay | DCR-2C-T | Honeywell (USA) | |

11. | Circuit breaker |

| zhengtai | |

12. | button | SAY7-B-G/Y/R | Shanghai Senao | |

1. | Main electric motor |

| ZD or Miley |

Lifting Machine |

2. | Solid-state relay | DD4825 | Meel (Shanghai) | |

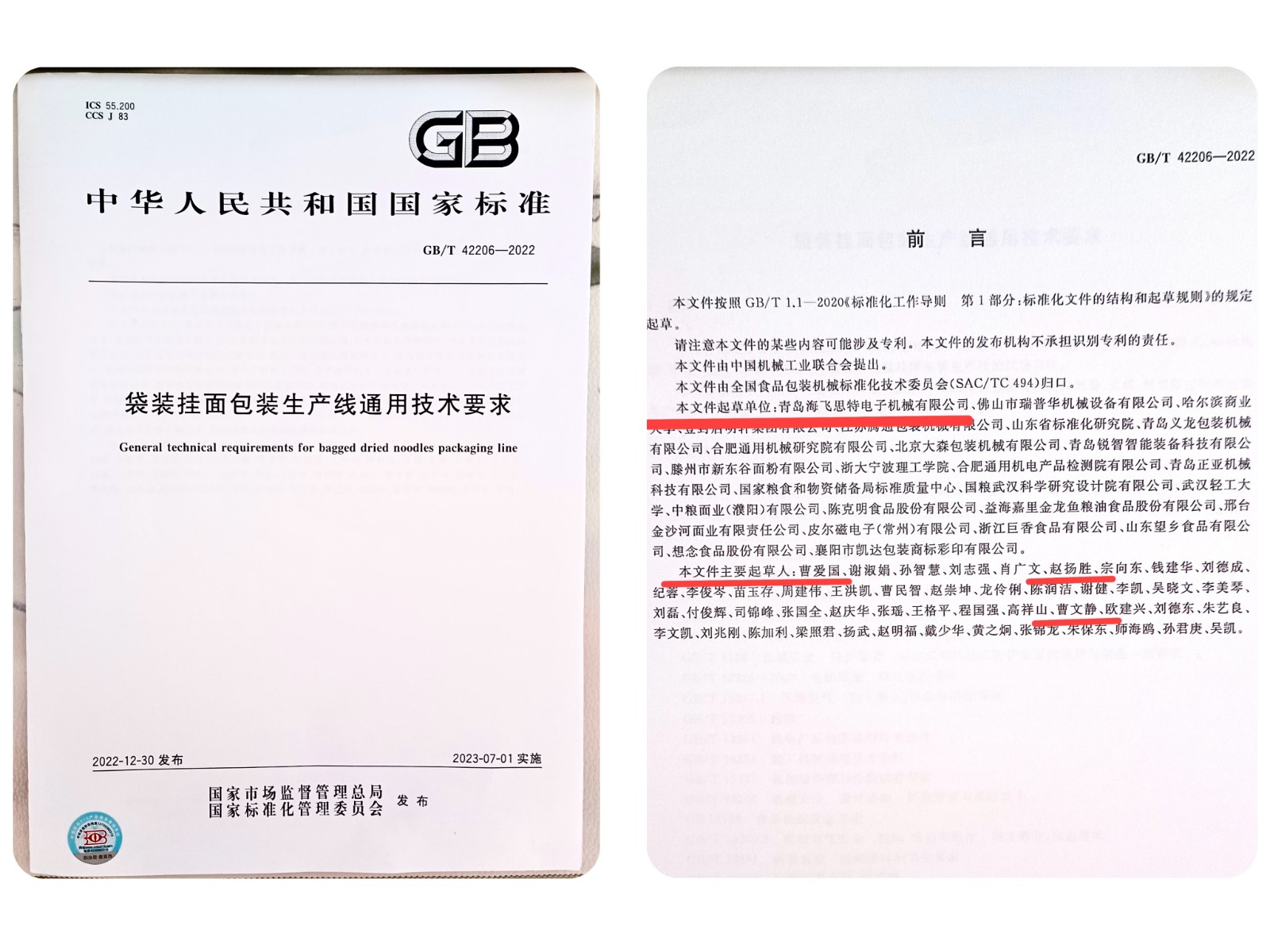

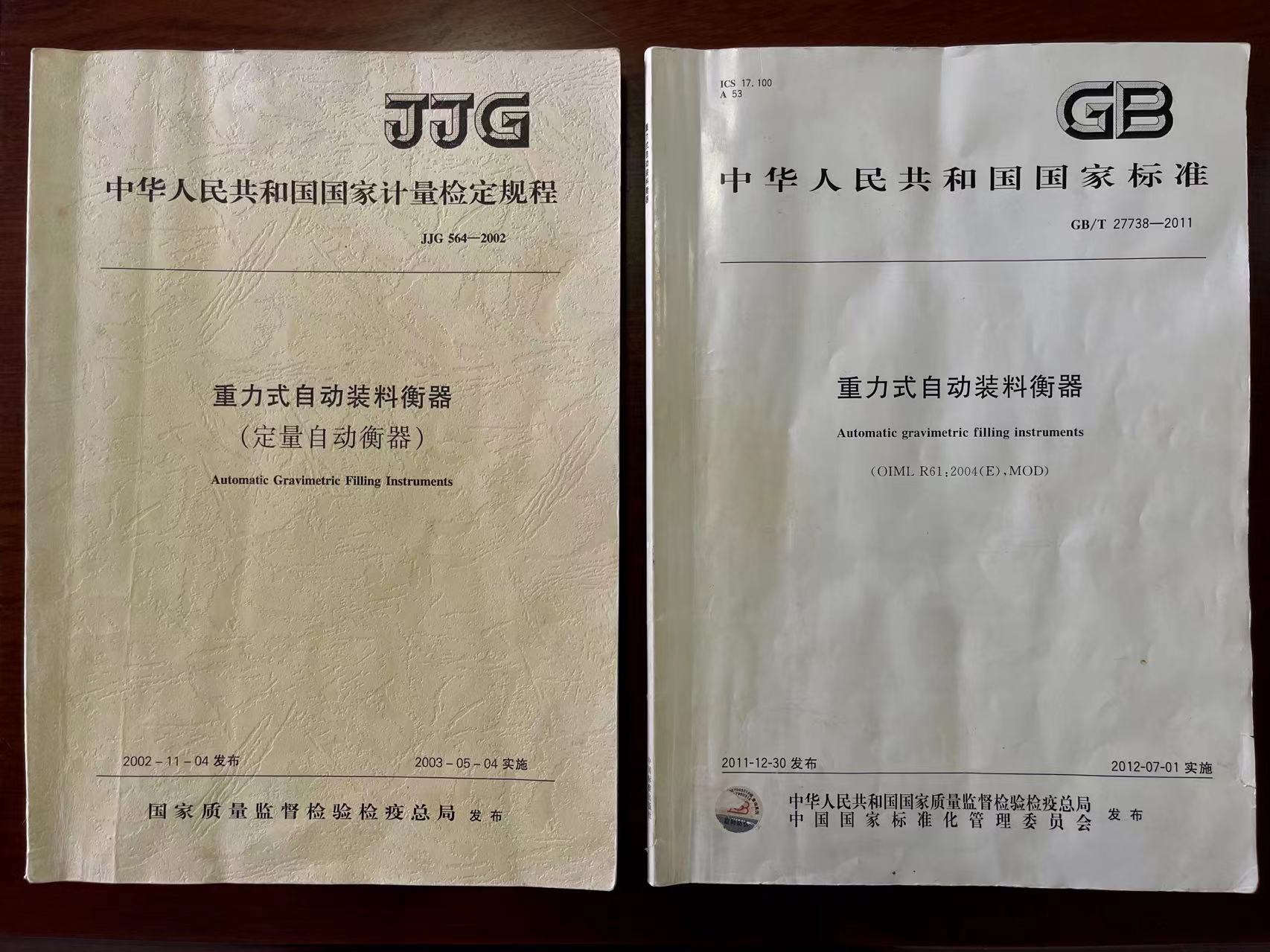

Our noodle packaging machine is a patented product in China, assisting China's General Administration of Quality Supervision, Inspection and Quarantine and China's National Standardization Administration to jointly draft national standardization specifications for noodle packaging.

patent certificate