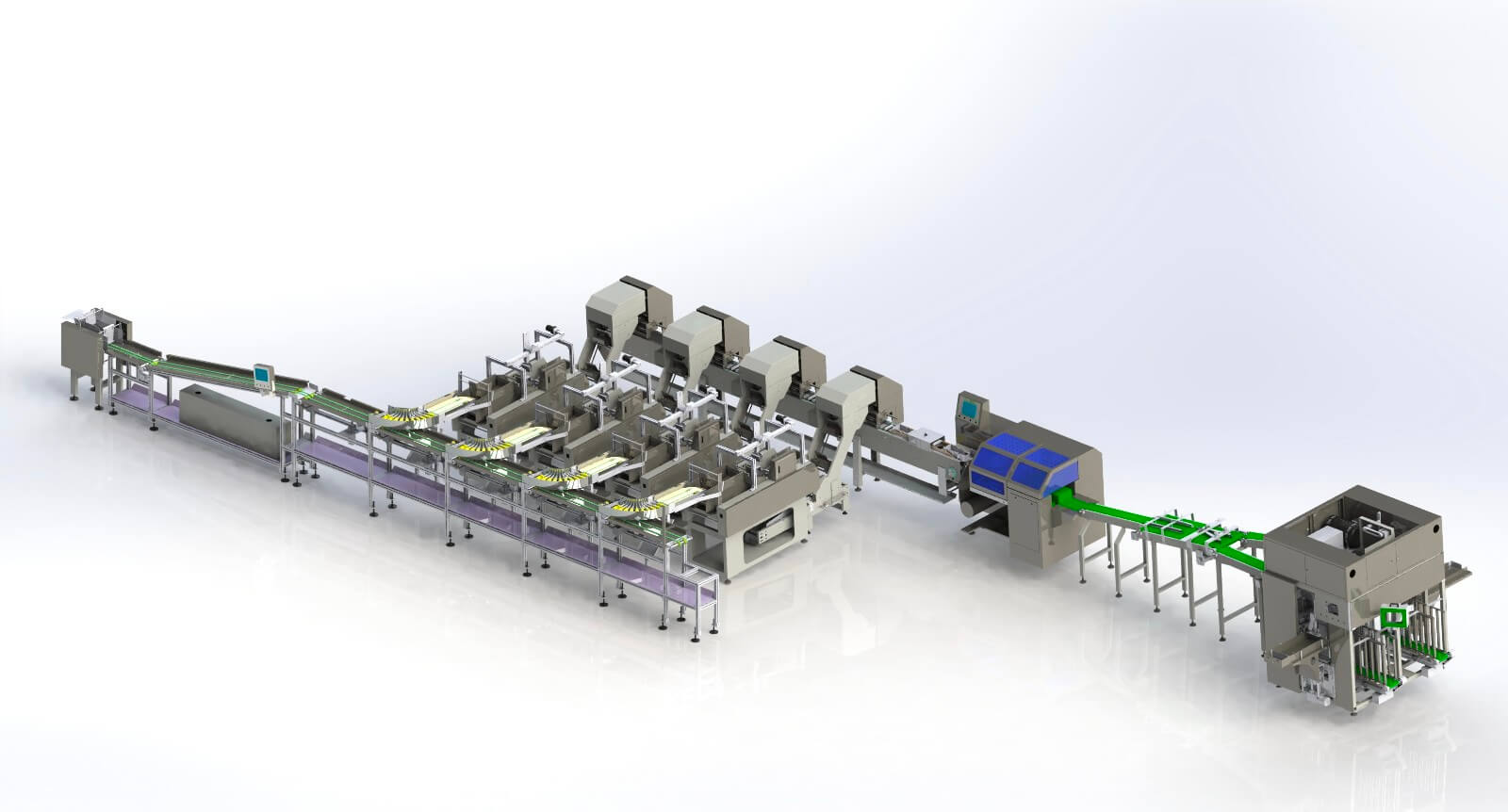

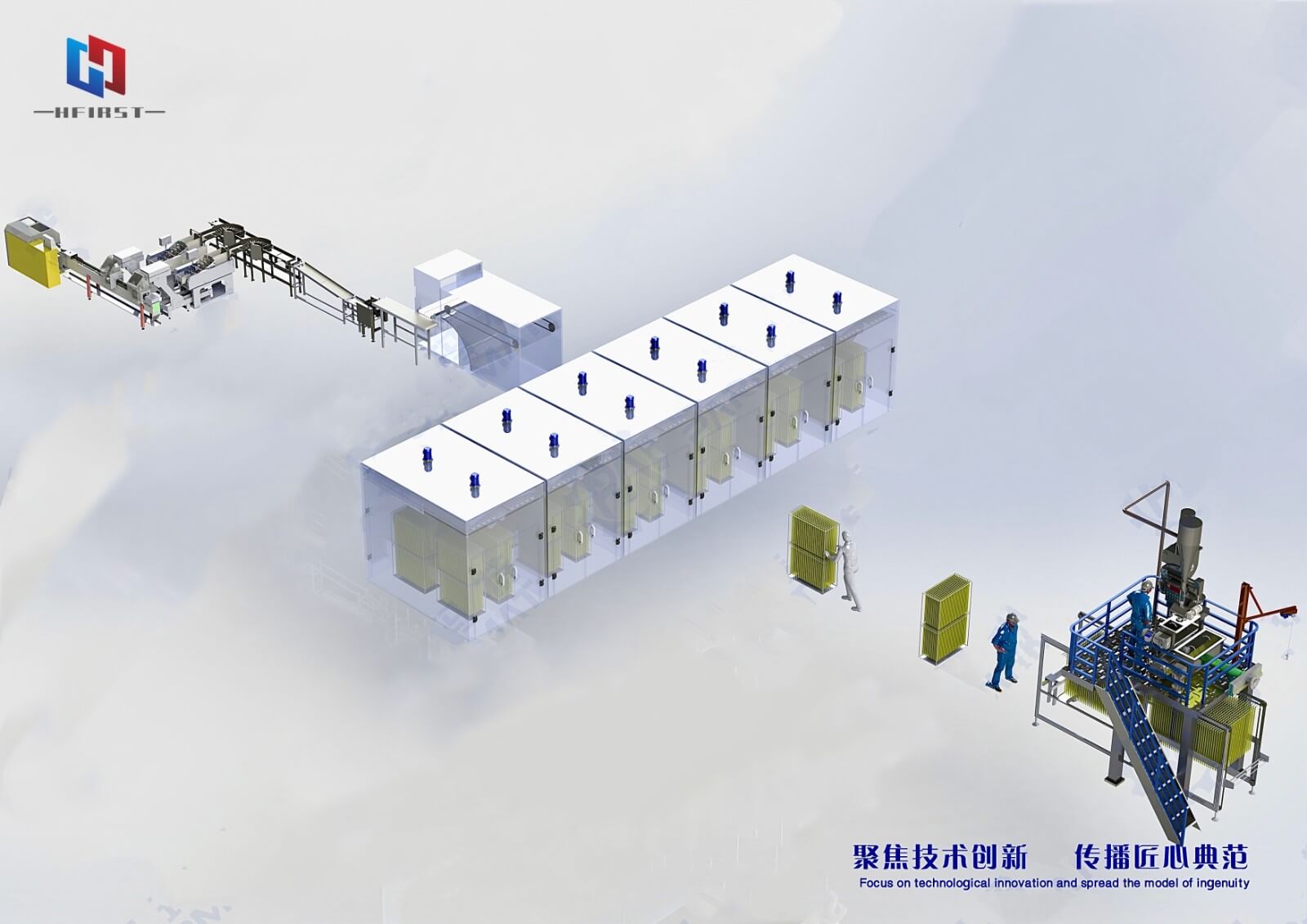

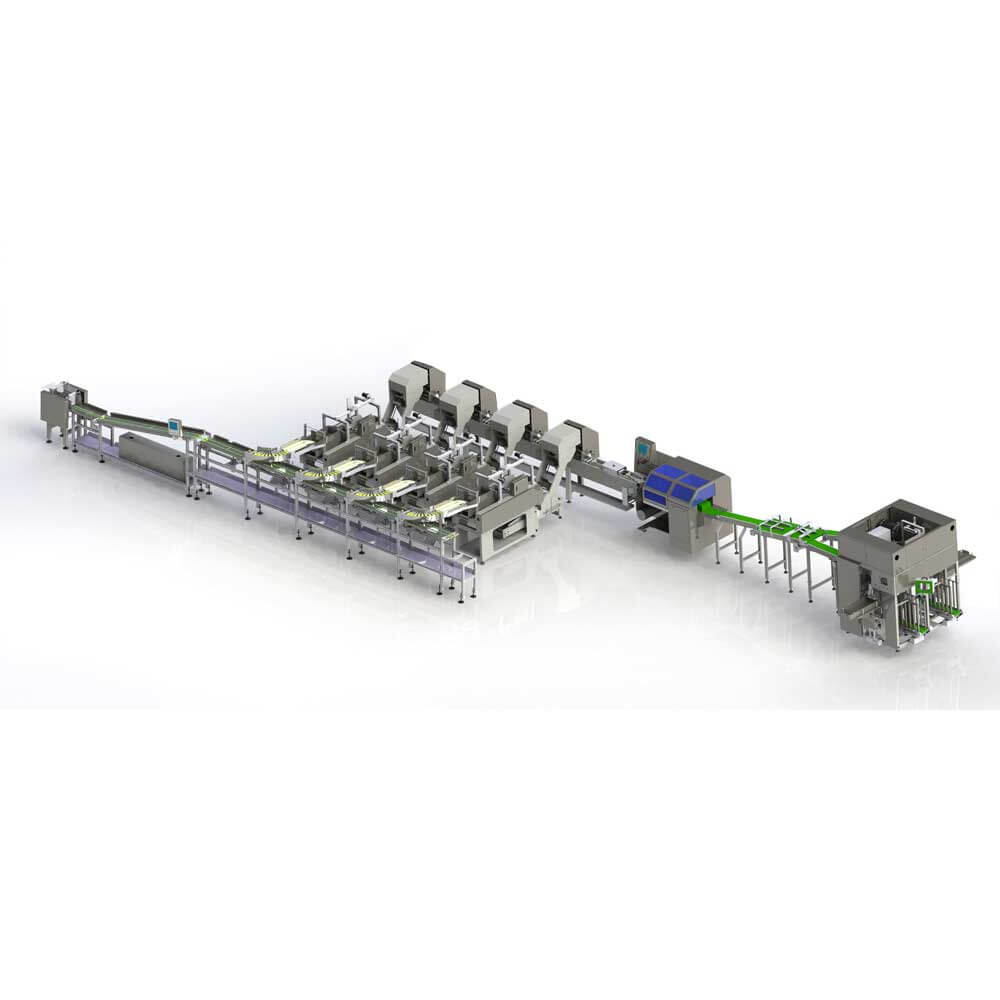

Noodle Production Line

Hfirst Noodle production line has 20 years of research and development and manufacturing experience in China. Applicable to bulk strip-shaped materials such as: dry noodles, Udon noodles, stick noodles automatic making, dry, weighing and packaging. Fully automatic and high-precision weighing and high-speed packaging, controlled by a highly intelligent system, with strong stability and stainless steel material meeting food grade standards. The 8000 square meter production and manufacturing workshop has a R&D technical team of over 20 people and over 100 employees. We have CE and ISO9001 certifications, over 30 national technology patents, and have led the development of Chinese national technical standards for noodle packaging.Products are sold to countries such as the United States, North America, South America, Africa, and Europe.

Details

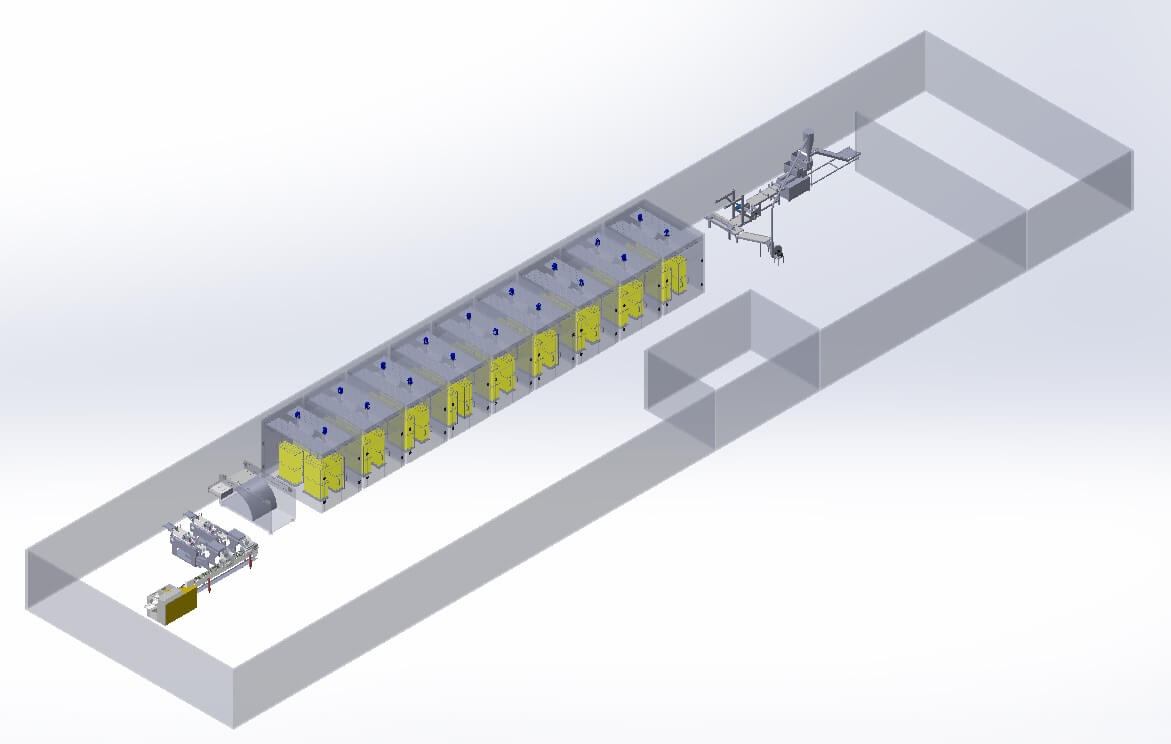

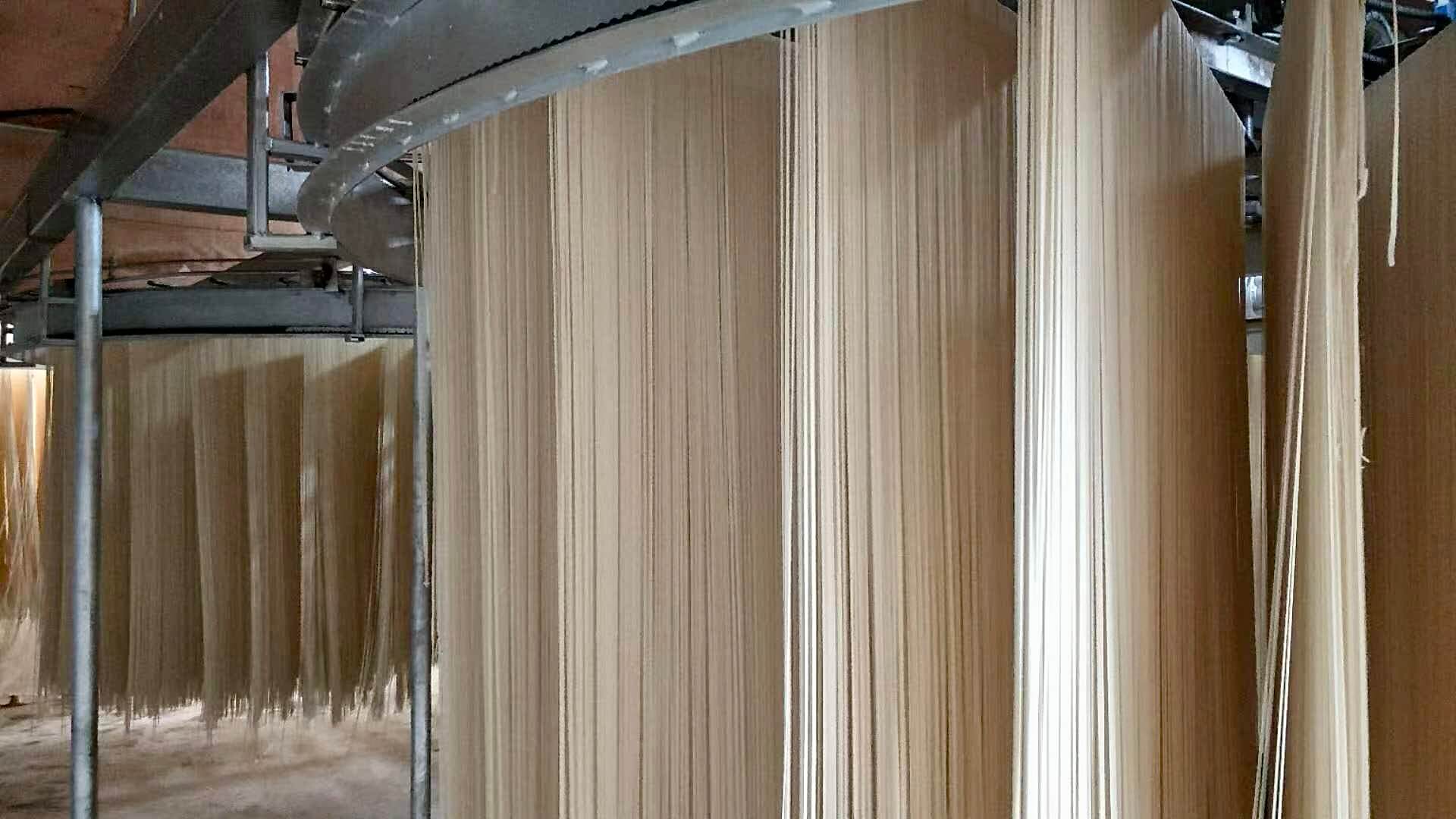

Noodle Production Line

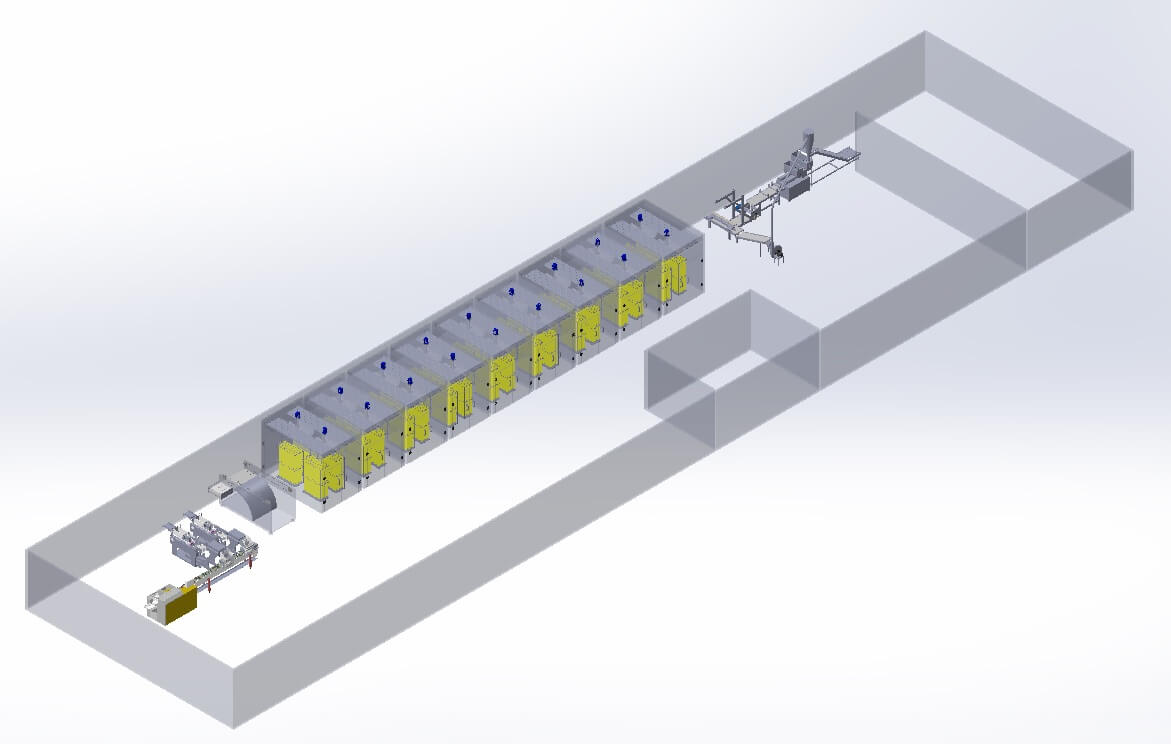

Noodle Production Line is used Fine dried noodles. Stick Fine dried noodles are one of the staple foods in Asia, especially in China. The noodles made by our company are rich in product types, and the shape, length and thickness of the noodles can be customized according to the needs of customers. It has big capacity while use small area, less labor, lower energy consumption, which is the first choice for stick noodle mass production and very popular among users. The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying. Automatic noodle up-conveying, down-conveying, cutting and packing have lighten labor force and improved sanitation. The daily output is from 8 tons to 90 tons.

Automatic Noodle Machine is one type of noodle processing machine, first you need to mix the wheat flour with water by flour mixer, then put them into the noodle machine, and then can press into noodle automatically. It can dived to small type noodle machine, middle type noodle machine and noodle production lines.You can use the machine to make any size and any shape noodle, inlude round noodle, square noodle, dry noodle, fresh noodle etc, only to change the mould. The machine constitute with the frame, rollers and motors etc. We have different models , from 40kg/h to 2000kg/h, the machine capacity is different. Our machine have multiple functions. It is widely used in western food shop, snack food factory, tea restaurant, chinese restaurant, bakery shop, coffee shops etc.

Why choose us:

1.We are manufacturer and also have our own foreign trade team.

2.We have professional R&D staff who can make different design for your special request

3.Our professional workers will make the perfect noodle machine for you

4.We can send our engineer to your country for assembling and traning.

5.We can provide competitive price and high quality noodle machine to you.

6. we have been engaged in manufacturing Instant noodles making machine for 46 years, accumulating rich experience and enjoying high reputation.

7. Long term cooperation with more than 100 customers in more than 50 countries. Provide free technical support and layout solutions for more than 1000 potential customers.

8. we are manufacturer, Fast delivery and good service .All the machines are strictly inspected before making shipment. We can also provide customized equipment according to the noodle products you provide

9. We have ISO9001 and CE certificate,And more than 50 patent certificates

10. Installation and commision: we will send 2 technician to buyer's factory and Train employees how to operate.Warranty is for one year

| Model | MT7-300 | MT6-300 | MT7-260 | MT6-260 | MT5-250 |

| Roller Groups | 7 | 6 | 7 | 6 | 5 |

| Width of Roller | 300mm | 300mm | 260mm | 260mm | 250mm |

| Output | 240kg/h | 200kg/h | 200kg/h | 200kg/h | 120kg/h |

| Power | 4kw | 4kw | 4kw | 3kw | 3kw |

| Weight | 900kg | 800kg | 800kg | 700kg | 500kg |

| Size | 2600*680*1350MM | 2350*680*1350MM | 2600*640*1350MM | 2350*640*1350MM | 1100*880*1000mm |

| Model | MT5-200 | MT-125 | MT-100 | MT-80 | MT-60 | MT-40 |

| Roller Groups | 5 | 1 | 1 | 1 | 1 | 1 |

| Width of Roller | 200mm | 120mm | 120mm | 102mm | 91mm | 88mm |

| Output | 80kg/h | 60kg/h | 60kg/h | 50kg/h | 40kg/h | 30kg/h |

| Power | 2.2-3.0kw | 1.5kw | 1.5kw | 2.2kw | 2.2kw | 1.5kw |

| Weight | 320kg | 160kg | 140kg | 117kg | 102kg | 75kg |

| Model | MT9-550 | MT8-550 | MT7-450 | MT7-400 | MT6-350 |

| Roller Groups | 9 | 8 | 7 | 7 | 6 |

| Width of Roller | 550mm | 550mm | 450mm | 400mm | 350mm |

| Output | 1000kg/h | 900kg/h | 550kg/h | 450kg/h | 400kg/h |

| Power | 15kw | 15kw | 13kw | 11kw | 4kw |

| Weight | 7.3T | 6.5T | 3.8T | 3.3T | 1300kg |

| Size | 8700*1600*1500MM | 8100*1600*1500MM | 5200*1250*1400MM | 5200*1200*1400MM | 2400*880*1400mm |

The backend is equipped with a cutting machine and a fully automated packaging production line, achieving full automation of the workshop and providing customized solutions for you. Our machine exported to sri lanla, india, Austrlia, USA, Canada etc.